Basic Info.

Product Description

Oxygen Gas Generation Equipment For Hospital

Oxygen Gas Generation Equipment For Hospital

With PSA principles, ETR PSA medical Oxygen Gas Generation Equipment can produce 93%±3% purity oxygen gas directly from compressed air. Compared with traditional Bulk liquid oxygen and cylinders oxygen, ETR on-site PSA medical Oxygen Gas Generation Equipment can reduce cost down to 50%. They can produce oxygen by your will, overcoming the limits of distance, location and transportation.

Compressed air is purified through the air dryer and filters to a certain level for main generator to work with. Air buffer is incorporated for smooth supply of compressed air thus to reduce fluctuation of compressed air source. The medical Oxygen Gas Generation Equipment produces oxygen with PSA (pressure swing adsorption) technology, which is a time proven oxygen generation method. Oxygen of desired purity at 93%±3% is delivered to oxygen buffer tank for smooth supply of product gas. Oxygen in buffer tank is maintained at 4bar pressure.

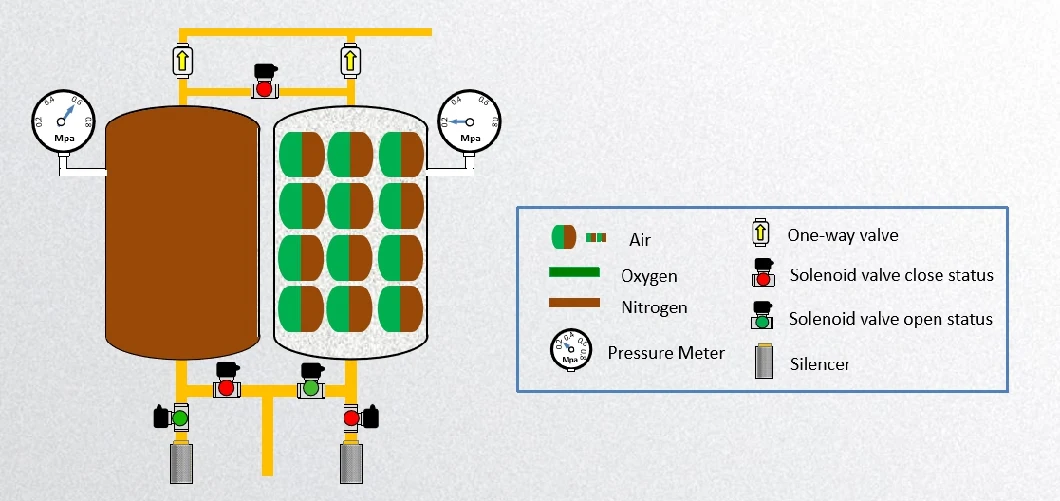

Working Principles

The medical molecular sieve PSA medical Oxygen Gas Generation Equipment applies the international advanced pressure swing adsorption (PSA) technology to form a rapid cycle of pressurization adsorption and depressurization desorption under the conditions of normal temperature and low pressure.

Features

1) More Economical:100,000-hour service life(more than 10 years), Completely automatic, labor cost saved, 0.15 dollar cost per cube meter.

Stable oxygen purity. 24 hour safe oxygen usage.

2) More Convenient: The system can be controlled by computer automatically, LCD touch screen interface, it is easy to operate and run.

No need for complex operation such as purchase,transportation,storage,canning etc. online oxygen monitor, remote monitoring system.

3) Energy - Saving and Environmentally Friendly: The raw material is air, which is easy to be gotten.

Low noise, physical process, gas control system, no pollution.

No need to transport oxygen by cylinders because the connected pipes system is equipped.

4) Safety: Time Proven PSA (pressure swing adsorption) technology to separate the oxygen from the air directly. No split charging during shipment, which decreases the safety risks. Issuing alarm signal against abnormal parameters.

Model Select

Item | Model | Capacity | Dimension(MM) | NW | Power | Connector | |

Air Inlet | Oxygen Outlet | ||||||

1 | ETO-03 | 3 | 760×750×1850 | 380 | 60 | DN15(G1/2") | DN15(G1/2") |

2 | ETO-05 | 5 | 760×750×2200 | 450 | 60 | DN15(G1/2") | DN15(G1/2") |

3 | ETO-10 | 10 | 880×780×2400 | 780 | 60 | DN20(G3/4") | DN15(G1/2") |

4 | ETO-15 | 15 | 1070×940×2500 | 1080 | 60 | DN25(G1") | DN20(G3/4") |

5 | ETO-20 | 20 | 1450×950×2500 | 1260 | 60 | DN32(G11/4") | DN20(G3/4") |

6 | ETO-30 | 30 | 1500×1000×3000 | 1680 | 60 | DN40(G11/2") | DN25(G1") |

7 | ETO-40 | 40 | 1750×1200×3150 | 2150 | 60 | DN40(G11/2") | DN25(G1") |

Note: Customization is acceptable. | |||||||

Model ETO-15

Item | Specification | Remark |

Oxygen Capacity | 1-60Nm3/h | Normal/Standard Condition |

Oxygen Purity | 93%±3% |

|

Oxygen Delivery Pressure | 4bar | Adjustable |

Power Consumption | 60KW | 220V, 50Hz @1Phase |

Dimensions (mm) | / | Including buffer tanks. Dimensions are approximate. |

Weight (kg) | / | Weight is approximate. |

Noise Level | ≤85dB(A) | 1 meter away |

Compressed Air Specifications | ||

Air Flow Rate Required | As per model | Capacity Of The Clean & Dry Air after Pretreatment |

Pressure | ≥7bar | Gauge |

Oil residual Content | ≤0.008PPm |

|

Particles Size | ≤0.01m |

|

Pressure Dew Point | + 3ºC |

|

Air Temperature | 5-45 Deg. C |

|

Design Working Conditions | ||

Relative humidity | 20%-100% |

|

Dust Content In The Air | ≤20mg/m3 |

|

H2S,SO2 Content In The Air | ≤5ppm |

|

CO2 Content In The Air | ≤250ppm |

|

CnHm Content In The Air | ≤20ppm |

|

Acidic Gases | Less Than Stimulus | Self-governed Room For Air Separation Plant And Far From Acidic Environment is Strongly Recommended |

Content And Without Erosive Gases | ||

FAQ

1. Are you manufacturer or trading Company?

We are the manufacturer of medical oxygen generator, founded in 2003.

2. What's the order process of medical Oxygen Gas Generation Equipment?

a. Inquiry---please kindly provide us all specific requirements.

b. Quotation---official quotation form with all specifications will be provided.

c. Printing file--- PDF, Ai, CDR, PSD, the picture resolution has to be at least 300 dpi.

d. Contract confirmation---official contract will be issued before production process.

e. Payment terms--- Negotiable.

f. Production---mass production.

g. Shipping--- by sea, air or courier. Detailed pictures of package will be provided.

h. Installation and commissioning

3. What terms of payment is acceptable?

T/T, L/C, etc.

4. How to get a prompt quotation of medical Oxygen Gas Generation Equipment?

Pls kindly give us your order requirements with below technical information:

1) O2 flow rate: _____Nm3/hr( or How many cylinders do you want to fill per day/24hours)

2) O2 purity: _____%

3) O2 discharge pressure: _____Bar

4) Voltages and Frequency : ______V/PH/HZ

5) Application:

6) Project Location: